Should I Use Crimp or Solder Termination for Cable Assemblies?

Cable termination is how a cable is connected to a power source, ensuring a secure and reliable connection. There are many different cable termination methods. Two of the most common are crimping and soldering. But what’s the difference between them?

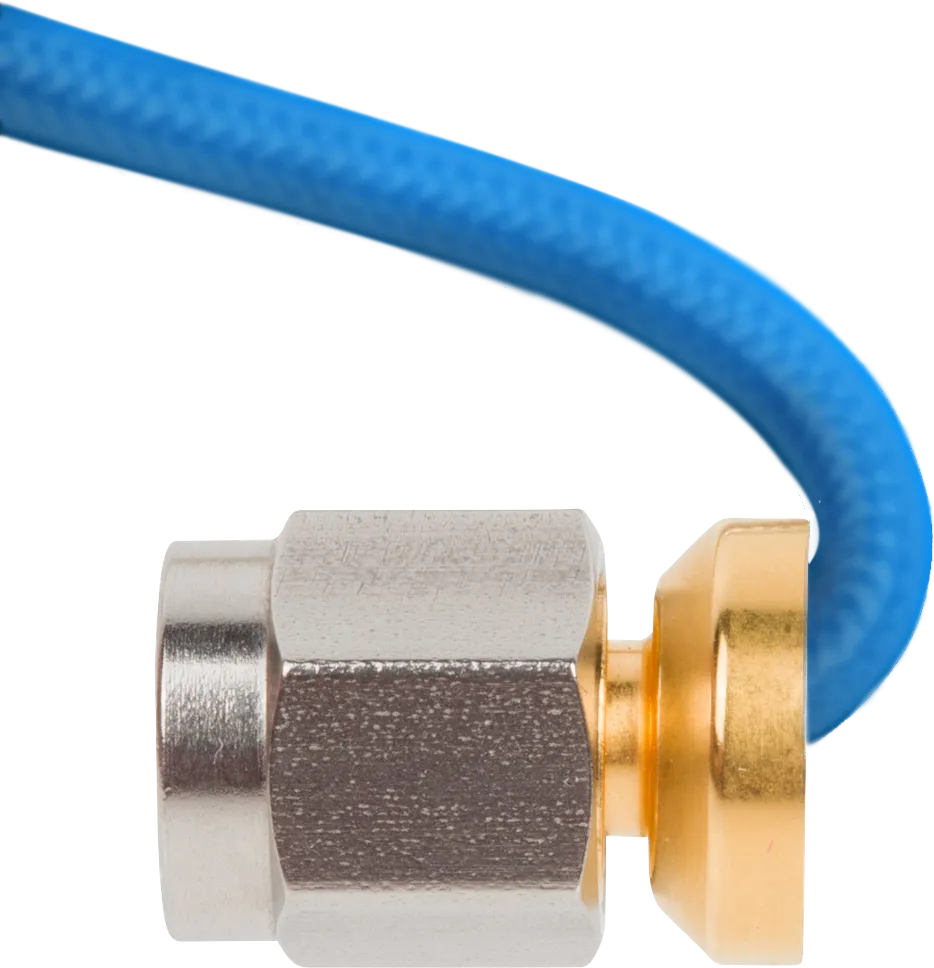

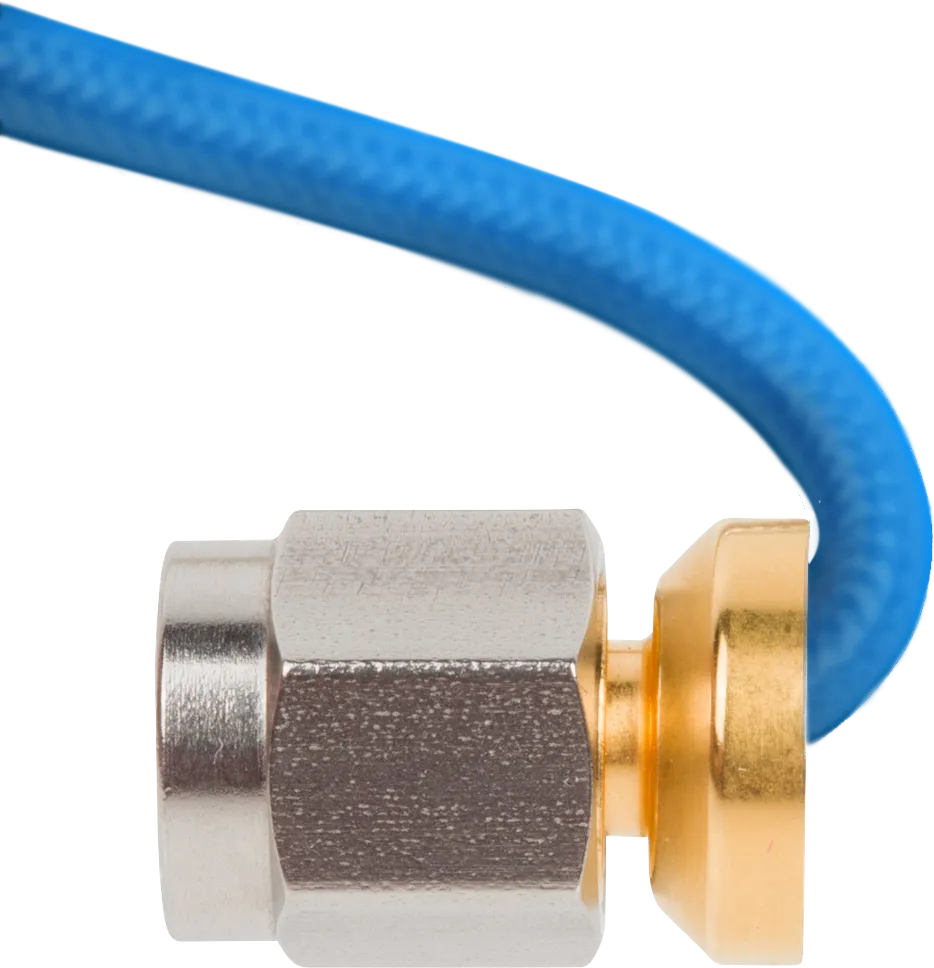

Crimp Termination

Crimp termination is done by flaring the cable braid over the back section of the cable connection. The brass sleeve is then crimped over the termination. This method is often used in low-reliability, low-frequency, and low-performance applications.

Benefits

- Eliminates solder-wicking in the cable braid

- Allows for tight turns in a cable assembly

- Quick and repeatable

Downsides

- Loses favor in higher frequency applications

- Weaker and less reliable than a soldered joint

- Requires the right tooling and calibration

- Unable to rework — once a connector is crimped, it can not be reworked, and the assembly is scrapped

- Because it cannot be reworked, precision phase matching is not possible

Solder Termination

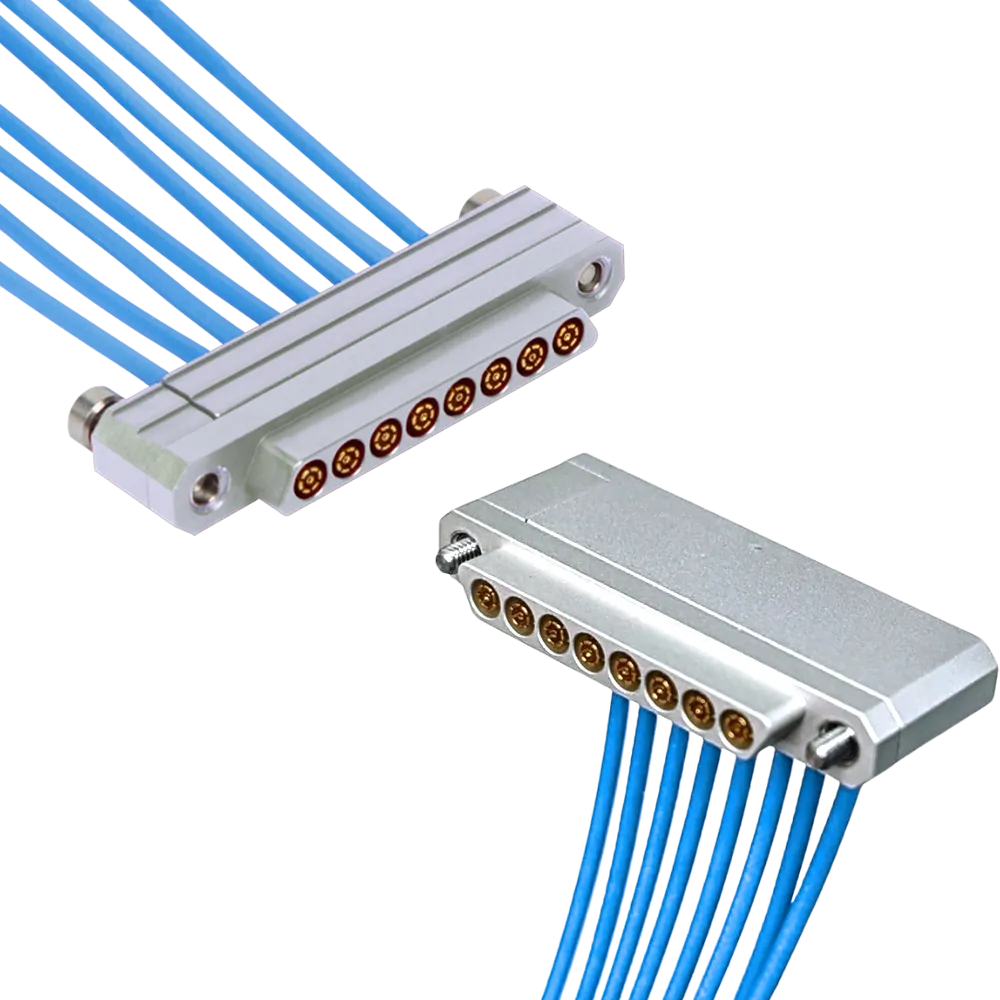

Low Profile Cable Assemblies with Solder Termination

Solder Termination uses solder to create a strong bond between the cable and connector. It’s often used in PCB-integrated, high-frequency, high-performance, and high-reliability applications.

Benefits

- Excellent conductivity (lower loss)

- Economical

- Solder joint is reworkable

- Precision phase matching can be accomplished

Downsides

- Slower and more nuanced process than crimping

- Higher cost to train and maintain operators, and for the soldering process

Solder Reliability

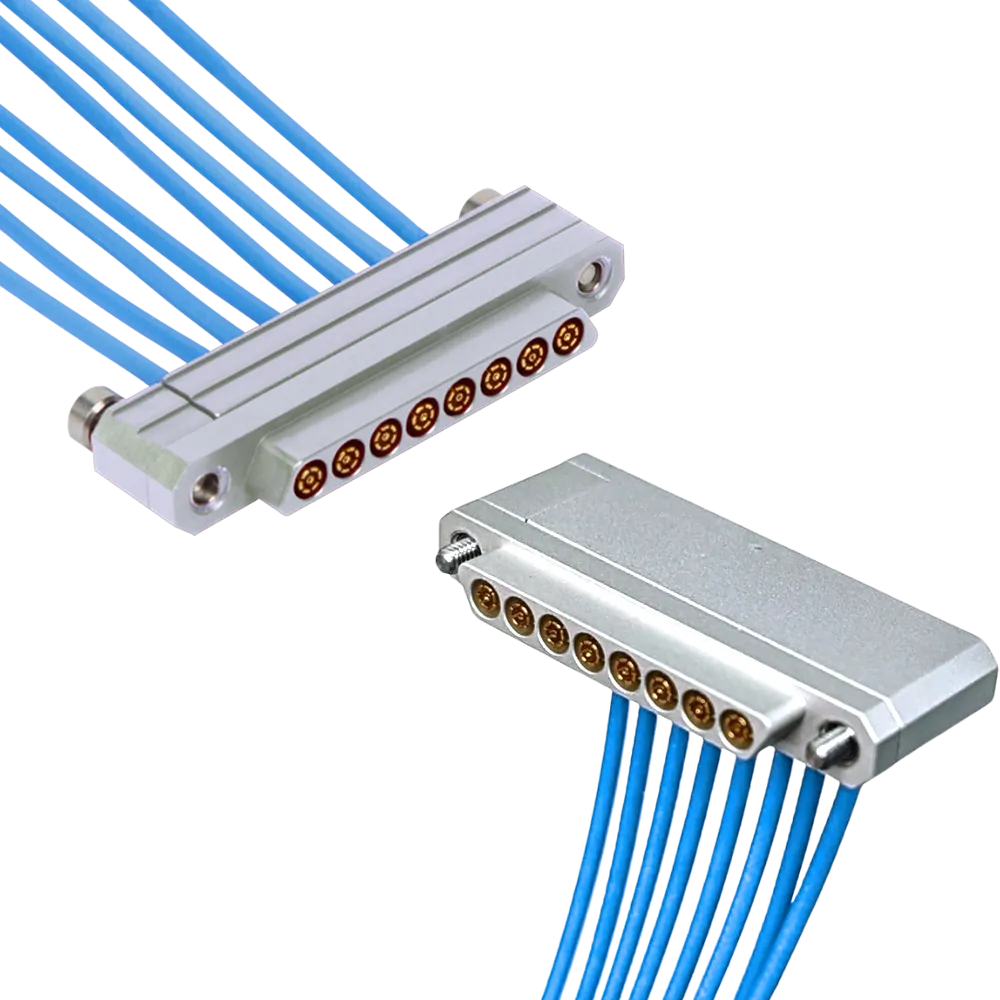

Mini-D RF Cable Assemblies with Solder Termination

When you’re looking for a cable assembly that can reliably perform long-term in high-frequency, high-performance applications, solder termination is your best bet. While crimp terminations can save a few minutes on the production line and work for low-frequency, low-performance applications, they don’t hold up when compared to solder.

At SV Microwave, our solder termination cable assemblies are engineered for precision, durability, and repeatable excellence. Explore our complete line of high-performance connectors and cable assemblies, and see why SV Microwave is trusted for mission-critical reliability.

recent releases

Should I Use Crimp or Solder Termination for Cable Assemblies?

Cable termination is how a cable is connected to a power source, ensuring a secure and reliable connection. There are many different cable termination methods. Two of the most common are crimping and soldering. But what’s the difference between them?

Crimp Termination

Crimp termination is done by flaring the cable braid over the back section of the cable connection. The brass sleeve is then crimped over the termination. This method is often used in low-reliability, low-frequency, and low-performance applications.

Benefits

- Eliminates solder-wicking in the cable braid

- Allows for tight turns in a cable assembly

- Quick and repeatable

Downsides

- Loses favor in higher frequency applications

- Weaker and less reliable than a soldered joint

- Requires the right tooling and calibration

- Unable to rework — once a connector is crimped, it can not be reworked, and the assembly is scrapped

- Because it cannot be reworked, precision phase matching is not possible

Solder Termination

Low Profile Cable Assemblies with Solder Termination

Solder Termination uses solder to create a strong bond between the cable and connector. It’s often used in PCB-integrated, high-frequency, high-performance, and high-reliability applications.

Benefits

- Excellent conductivity (lower loss)

- Economical

- Solder joint is reworkable

- Precision phase matching can be accomplished

Downsides

- Slower and more nuanced process than crimping

- Higher cost to train and maintain operators, and for the soldering process

Solder Reliability

Mini-D RF Cable Assemblies with Solder Termination

When you’re looking for a cable assembly that can reliably perform long-term in high-frequency, high-performance applications, solder termination is your best bet. While crimp terminations can save a few minutes on the production line and work for low-frequency, low-performance applications, they don’t hold up when compared to solder.

At SV Microwave, our solder termination cable assemblies are engineered for precision, durability, and repeatable excellence. Explore our complete line of high-performance connectors and cable assemblies, and see why SV Microwave is trusted for mission-critical reliability.