Prevent Damage to Your PCB Trace

Traditional threaded RF PCB edge launch connectors can cause damage to the PCB board trace when torqued down during mating. That’s why SV Microwave created an innovative and robust connector design to prevent this damage.

The Problem

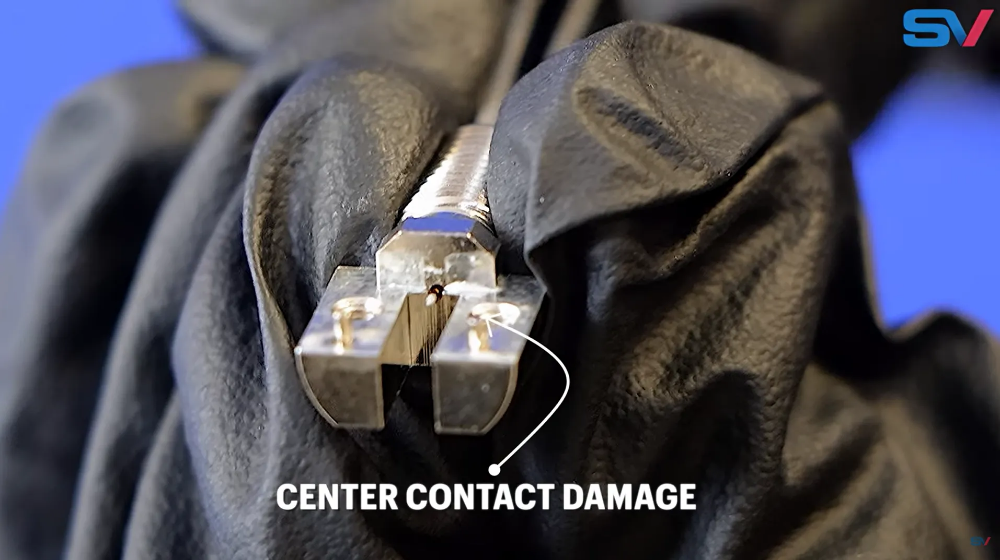

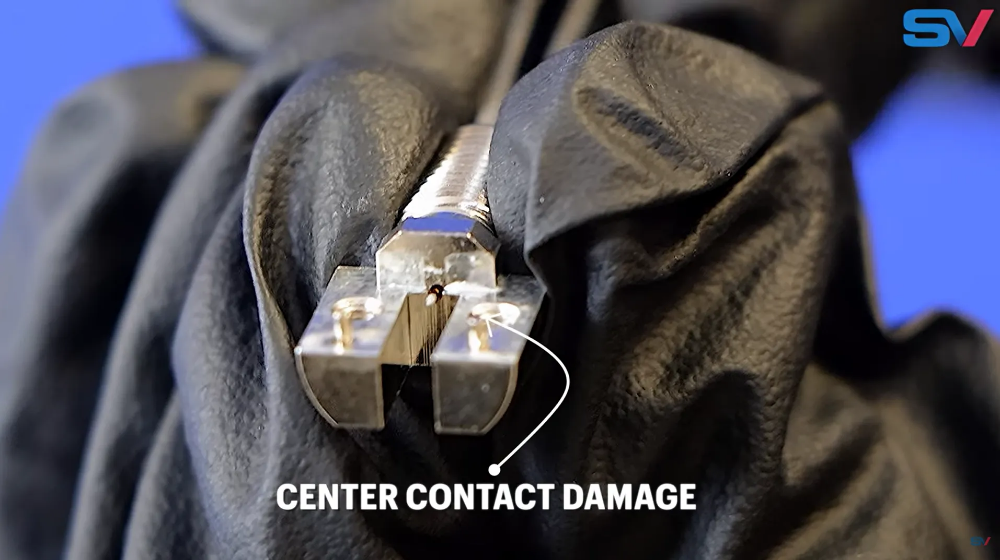

High-performance edge launch connectors rely on small-diameter center contacts for optimum transitions. This contact is captivated in plastic and can rotate inside this material when torqued down during mating, typically by the mating center contact.

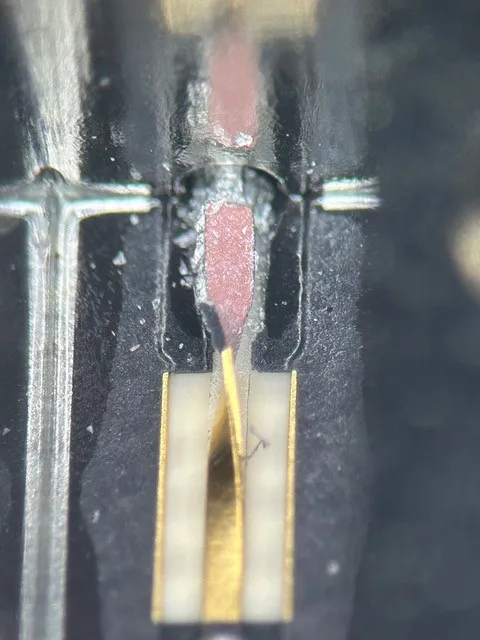

If the center contact on the edge launch is already soldered to the board and rotates, it will rip the trace off the board, so it can keep spinning. As shown below, the PCB is destroyed when this happens, which is typically a very expensive problem.

Additionally, the chances for damaged solder joints or delaminated traces can be raised from user error or wear and tear from repeated mating cycles.

So, how do we avoid this?

SV’s Solution

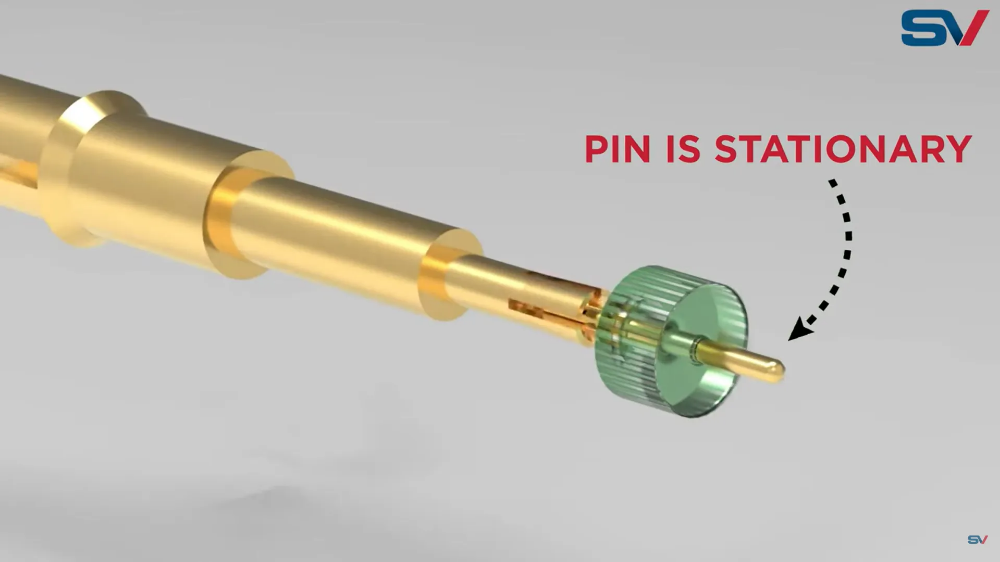

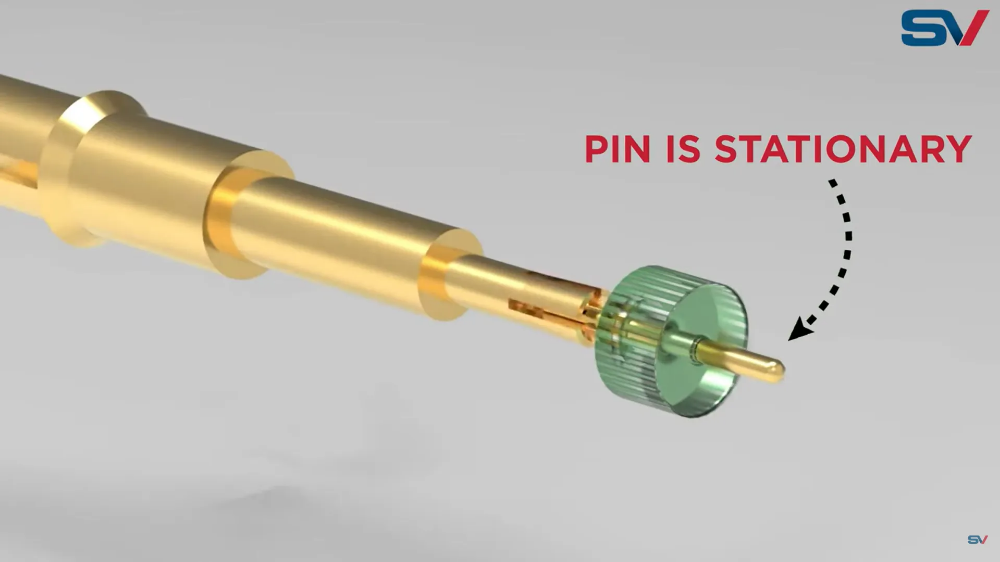

SV Microwave’s TraceGuard Edge Launch RF PCB Connectors, formally known as our Torque Resistant Edge Launch RF PCB Connectors, have an innovative design that increases the rotational captivation of the center contact with a two-part contact assembly and glass seal captivation.

This fixes the soldered contact within the glass, therefore isolating any motion being transferred to the soldered connection and preventing damage to the PCB trace.

Additional Product Information

Features and Benefits

- Improved Rotational Captivation

- Maintains solder joint integrity on the PCB

- Features screws to help with fixturing

- DC up to 50 GHZ

Applications

- 5G Communications

- Printed Circuit Boards

- Test and Instrumentation

If you’re looking for a highly reliable connector, go to our website, where you’ll find our catalog of torque-resistant connectors, or reach out to our knowledgeable team of engineers at applications@svmicro.com

recent releases

Prevent Damage to Your PCB Trace

Traditional threaded RF PCB edge launch connectors can cause damage to the PCB board trace when torqued down during mating. That’s why SV Microwave created an innovative and robust connector design to prevent this damage.

The Problem

High-performance edge launch connectors rely on small-diameter center contacts for optimum transitions. This contact is captivated in plastic and can rotate inside this material when torqued down during mating, typically by the mating center contact.

If the center contact on the edge launch is already soldered to the board and rotates, it will rip the trace off the board, so it can keep spinning. As shown below, the PCB is destroyed when this happens, which is typically a very expensive problem.

Additionally, the chances for damaged solder joints or delaminated traces can be raised from user error or wear and tear from repeated mating cycles.

So, how do we avoid this?

SV’s Solution

SV Microwave’s TraceGuard Edge Launch RF PCB Connectors, formally known as our Torque Resistant Edge Launch RF PCB Connectors, have an innovative design that increases the rotational captivation of the center contact with a two-part contact assembly and glass seal captivation.

This fixes the soldered contact within the glass, therefore isolating any motion being transferred to the soldered connection and preventing damage to the PCB trace.

Additional Product Information

Features and Benefits

- Improved Rotational Captivation

- Maintains solder joint integrity on the PCB

- Features screws to help with fixturing

- DC up to 50 GHZ

Applications

- 5G Communications

- Printed Circuit Boards

- Test and Instrumentation

If you’re looking for a highly reliable connector, go to our website, where you’ll find our catalog of torque-resistant connectors, or reach out to our knowledgeable team of engineers at applications@svmicro.com