A Comparative Analysis of Dielectric Materials in PCB Connectors for Solder Reflow

In RF engineering, the selection of dielectric materials in PCB connectors plays a critical role in ensuring optimal performance, especially after solder reflow operations. The dielectric material around the center conductor within a PCB connector significantly impacts its ability to transmit RF signals effectively. This analysis delves into the characteristics of three prominent dielectric materials – PTFE, Epoxy, and Glass – to determine their suitability for solder reflow processes.

PTFE Dielectric

Polytetrafluoroethylene (PTFE), known for its high-temperature resistance and low dielectric constant, is a common choice in RF applications. However, PTFE has a relatively high CTE (coefficient of thermal expansion), which makes it susceptible to deformation at temperatures experienced during solder reflow, typically 221-225°C for lead-free solder (solder Sn96). This deformation due to thermal expansion can lead to compromised electrical and mechanical performance, as the dielectric material can move to places where it was not designed to be. In some cases, this can even lead to the dielectric pushing the connector off of the board and preventing contact with the trace.

Epoxy Dielectric

SV’s epoxy dielectric offers moderate temperature resistance with a lower CTE than PTFE. Compared to PTFE, this improves the connector’s compatibility with the solder reflow process. However, its application still has limitations. These limitations become apparent at higher reflow temperatures, where there is still the risk of material deformation affecting the overall integrity of the connector. However, epoxy as a dielectric material may offer cost-savings and significant improvement in lead times compared to connectors with glass dielectrics.

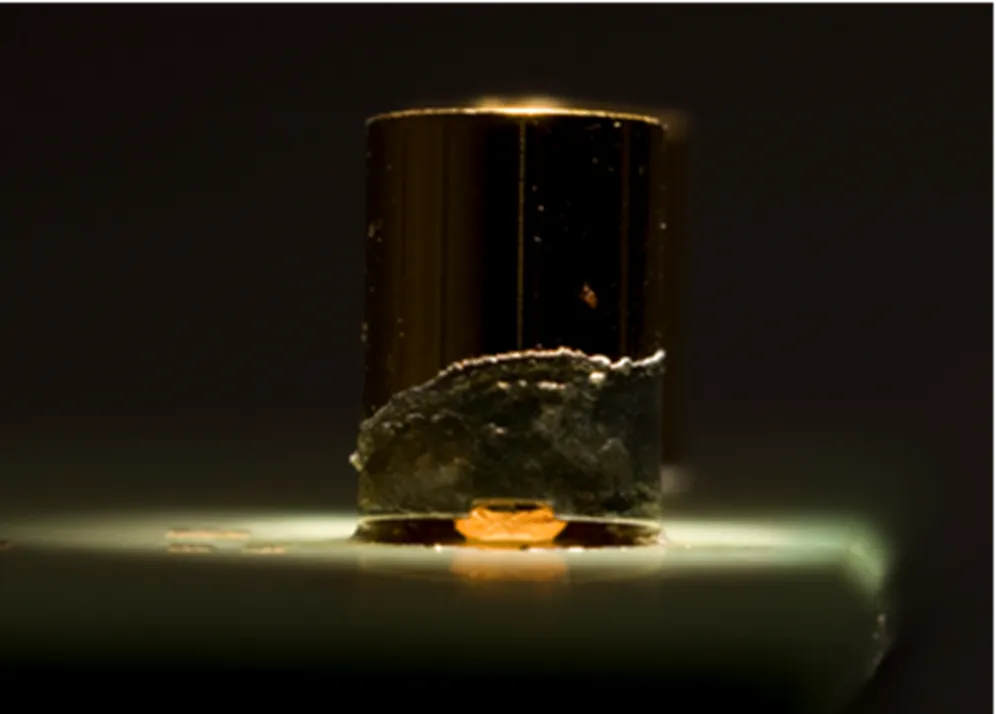

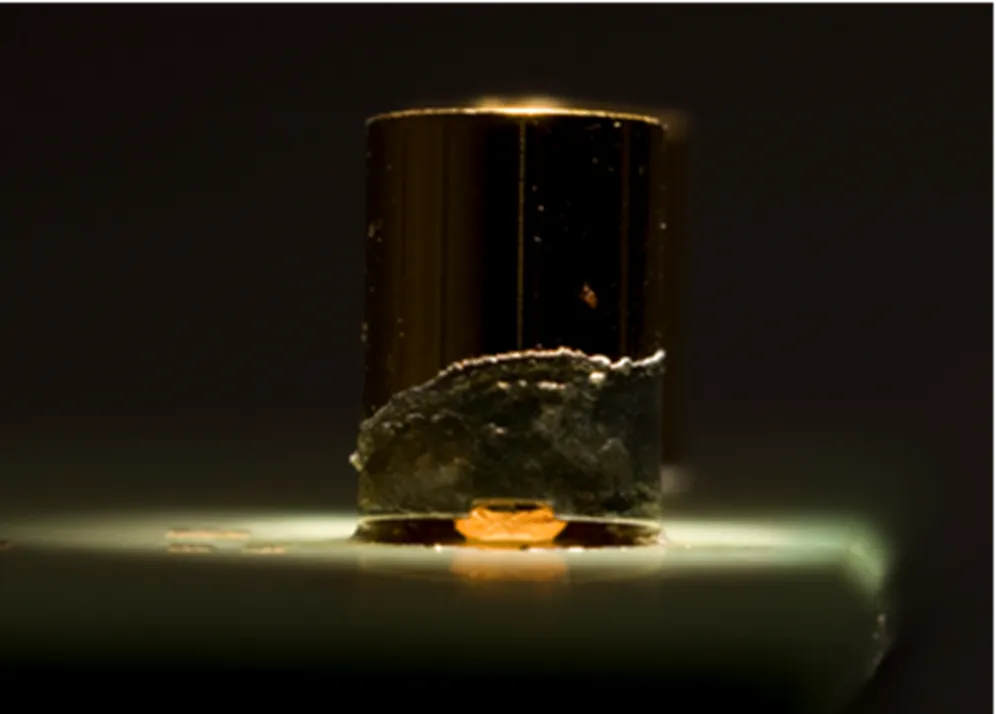

Glass Dielectrics

Glass dielectrics stand out for their exceptional thermal stability and very low CTE. As a dielectric, glass boasts a melting temperature of approximately 1068°C. This characteristic makes them highly resilient to the rigors of solder reflow processes, ensuring minimal impact on performance and reliability. The extremely low CTE of glass dielectrics eliminates concerns associated with temperature differentials, offering unparalleled consistency and durability during manufacturing and operation.

The choice of dielectric material significantly influences the performance and reliability of PCB connectors, particularly during solder reflow processes. While PTFE and Epoxy offer advantages in specific applications, their susceptibility to temperature variations renders them less suitable for demanding reflow conditions. In contrast, Glass-sealed dielectrics emerge as the superior choice, providing unparalleled thermal stability and consistent performance.

SV Microwave’s Reflow-stable product line stands out, with in-house capabilities to produce PCB connectors featuring Glass-sealed and epoxy dielectrics. This strategic advantage translates into reduced lead times and the flexibility to offer custom solutions tailored to specific customer requirements. With our commitment to innovation and quality, customers can trust in the reliability and performance of our RF products, setting us apart from competitors in the market.

The choice of dielectric materials is an important consideration when selecting RF PCB connectors commonly subjected to solder reflow. SV Microwave's dedication to excellence ensures that customers receive nothing short of superior application solutions.

recent releases

A Comparative Analysis of Dielectric Materials in PCB Connectors for Solder Reflow

In RF engineering, the selection of dielectric materials in PCB connectors plays a critical role in ensuring optimal performance, especially after solder reflow operations. The dielectric material around the center conductor within a PCB connector significantly impacts its ability to transmit RF signals effectively. This analysis delves into the characteristics of three prominent dielectric materials – PTFE, Epoxy, and Glass – to determine their suitability for solder reflow processes.

PTFE Dielectric

Polytetrafluoroethylene (PTFE), known for its high-temperature resistance and low dielectric constant, is a common choice in RF applications. However, PTFE has a relatively high CTE (coefficient of thermal expansion), which makes it susceptible to deformation at temperatures experienced during solder reflow, typically 221-225°C for lead-free solder (solder Sn96). This deformation due to thermal expansion can lead to compromised electrical and mechanical performance, as the dielectric material can move to places where it was not designed to be. In some cases, this can even lead to the dielectric pushing the connector off of the board and preventing contact with the trace.

Epoxy Dielectric

SV’s epoxy dielectric offers moderate temperature resistance with a lower CTE than PTFE. Compared to PTFE, this improves the connector’s compatibility with the solder reflow process. However, its application still has limitations. These limitations become apparent at higher reflow temperatures, where there is still the risk of material deformation affecting the overall integrity of the connector. However, epoxy as a dielectric material may offer cost-savings and significant improvement in lead times compared to connectors with glass dielectrics.

Glass Dielectrics

Glass dielectrics stand out for their exceptional thermal stability and very low CTE. As a dielectric, glass boasts a melting temperature of approximately 1068°C. This characteristic makes them highly resilient to the rigors of solder reflow processes, ensuring minimal impact on performance and reliability. The extremely low CTE of glass dielectrics eliminates concerns associated with temperature differentials, offering unparalleled consistency and durability during manufacturing and operation.

The choice of dielectric material significantly influences the performance and reliability of PCB connectors, particularly during solder reflow processes. While PTFE and Epoxy offer advantages in specific applications, their susceptibility to temperature variations renders them less suitable for demanding reflow conditions. In contrast, Glass-sealed dielectrics emerge as the superior choice, providing unparalleled thermal stability and consistent performance.

SV Microwave’s Reflow-stable product line stands out, with in-house capabilities to produce PCB connectors featuring Glass-sealed and epoxy dielectrics. This strategic advantage translates into reduced lead times and the flexibility to offer custom solutions tailored to specific customer requirements. With our commitment to innovation and quality, customers can trust in the reliability and performance of our RF products, setting us apart from competitors in the market.

The choice of dielectric materials is an important consideration when selecting RF PCB connectors commonly subjected to solder reflow. SV Microwave's dedication to excellence ensures that customers receive nothing short of superior application solutions.