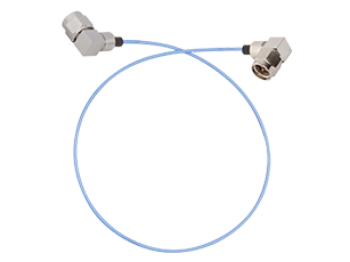

ConvergeRF Cable Assemblies

LTI Connector and Adapters

New Products

Top Sellers

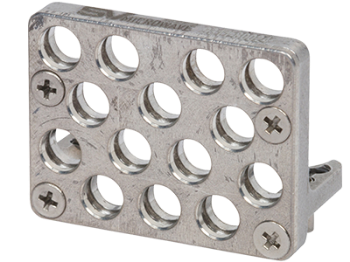

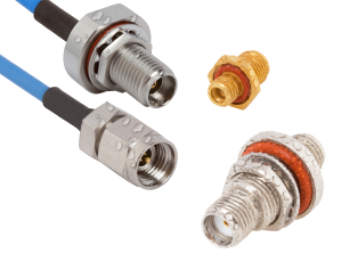

SF9321-60086

VITA Connectors SF9321-60086

3221-40066

VITA Connectors 3221-40066

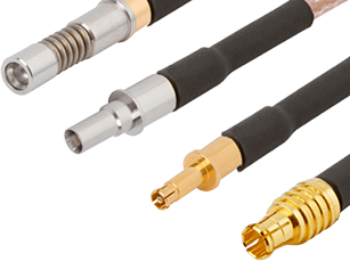

1290-4008

SMP Adapters 1290-4008

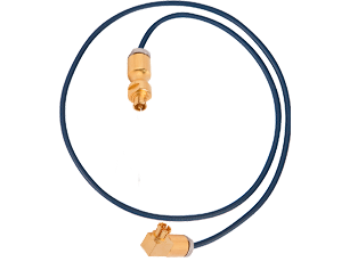

SF2991-6002

SMA Adapters SF2991-6002

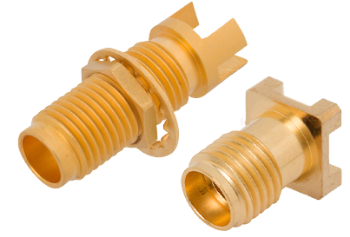

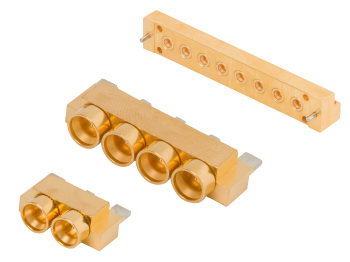

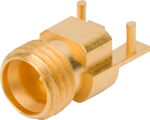

Part # SF1521-60070-1S

2.92mm Female Solderless PCB Compression Mount Connector, 2 Hole, with 4.76mm Screws (CPW / Microstrip)

Available Inventory: 1208

SF1521-60070-1S

2.92mm Connectors SF1521-60070-1S

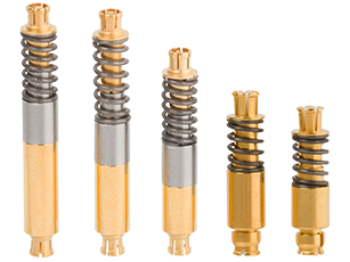

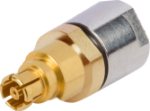

8032-4018

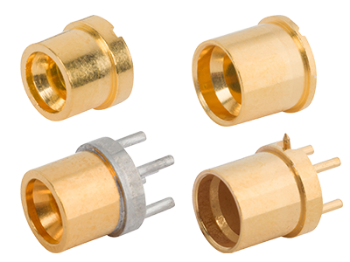

SMPM Components 8032-4018

3211-40121

SMPM Connectors 3211-40121

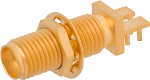

2921-00057

SMA Connectors 2921-00057

9311-00038

SMPM Connectors 9311-00038

3211-60298

SMPM Connectors 3211-60298

Upcoming Events

News

April 11, 2024

Distributors